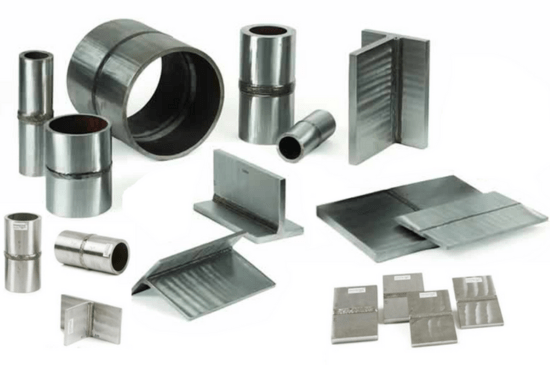

Products

Vanguard proficiency

Welcome to IDTechservices: your partner in the design, manufacturing and validation of parts for special NDT blocks, custom made.

Unlock the full potential of your non-destructive evaluation (NDE) capabilities with IDTechservices. Our range of services meets your specific needs and offers customized solutions for NDE training, procedure development, personnel training and qualification, specialized training and performance demonstration.

Custom Specimens Crafted to Your Vision:

At IDTechservices, we specialize in manufacturing custom samples designed to your exact specifications. Our dedicated team collaborates with you to bring your concepts to life. Through precision machining, the latest welding technologies and leveraging our in-house expertise, we create samples with defects that perfectly align with your unique requirements, simulating the exact conditions of your joints in manufacturing or in service. We have experience in the following materials.

- AC steel, structural.

- Carbon steel Pipes.

- Micro alloyed steels.

- Cr-Mo

- Automotive industry alloys.

- Cryogenic alloys. %Ni

- Stainless steels. Austenitic, duplex and martensitic.

- Special SS316 for fusion

- Inconel and Ni base Alloys.

- Aluminum alloys.

- Military Armor Steels.

- Lead.

Defective samples for various applications:

Whether you need to simulate worst-case failures during part construction or replicate specific in-service failures observed in the field, our custom samples are the ideal solution. We understand that each application is unique and our team is committed to designing and delivering defect samples that meet your precise needs.

Full documentation:

Each sample comes complete with detailed documentation, clearly identifying the types, sizes and locations of defects (truth of defect), manufacturing drawings, metrological control of defects, metallurgical reports, UT, PA, TOFD or RT reports, depending on is required. Our commitment to transparency ensures that you have all the information necessary for effective evaluation and training.

Request a quote – Worldwide:

Ready to elevate your NDE capabilities? Request a quote from IDTechservices today. Our services span the globe, bringing precision and expertise to your doorstep. Experience the difference of samples with defects tailored to your needs.

Contact us now to discuss your specific needs and let IDTechservices be your trusted partner in improving NDE proficiency.

Natural welding defect mock ups

Welcome to IDTechservices the specialist in natural defects to Elevate Precision in Non-Destructive Evaluation (NDE)

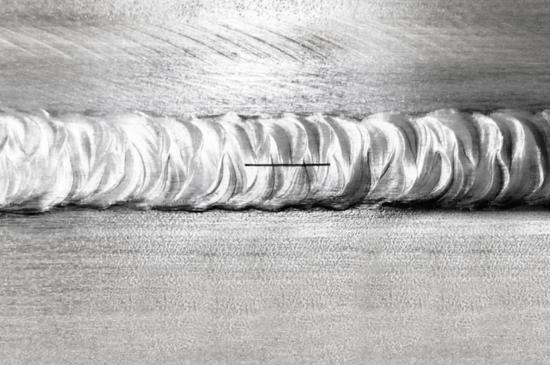

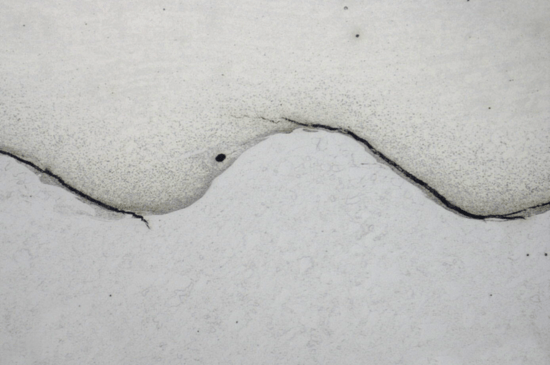

At IDTechservices, we offer calibration blocks with naturally induced defects designed to simulate common imperfections in the welding process, such as lack of fusion, lack of penetration, undercut, porosity, asymmetry, burn through, crater cracks, root oxidation, among other defects. These blocks are essential for equipment calibration and personnel training in the accurate detection of irregularities during non-destructive evaluation (NDE).

Customization of Calibration Blocks:

Our blocks are tailored to your specifications. We work closely with you to incorporate defects that simulate real-world situations, providing a wide range of imperfections from lack of fusion to porosity and sagging. Utilizing precision welding techniques and our in-house knowledge, we create blocks that precisely meet your needs.

Simulation of Welding Defects:

We understand the importance of simulating defects that occur during welding, and our calibration blocks offer a faithful representation of real-world conditions. They allow your NDE and IWE team to practice and refine their skills in detecting a variety of specific defects.

Welding Expertise and Advanced Technology:

To achieve this, we leverage the expertise of our highly skilled welding engineers and utilize the most advanced robotic welding equipment in the market. This combination of experience and technology enables us to create calibration blocks with exceptional precision, faithfully replicating defects that may arise during the welding process.

Importance for Inspection Procedures:

These blocks are particularly crucial for designing inspection procedures and scan plans. They provide your team with the necessary tools to develop and refine inspection methods that specifically align with the conditions and defects that may be encountered in your welding projects.

Defective samples for various applications:

Each calibration block comes with detailed documentation that clearly identifies defect types, sizes, and locations. Our commitment to transparency ensures that you have all the information needed for effective evaluation and precise training.

Full documentation:

- In-house expertise in precision machining and welding.

- Customized calibration blocks tailored to your needs.

- Accurate simulation of a wide range of welding defects thanks to our skilled engineers and advanced equipment.

- Special importance for designing inspection procedures and scan plans.

- Detailed documentation for precise evaluation.

- Lead.

Request a quote:

Ready to enhance your NDE capabilities? Request a quote from IDTechservices today. Our services extend worldwide, bringing precision and expertise to your doorstep. Experience the difference of calibration blocks adapted to a variety of specific defects.

Contact us now to discuss your specific needs, and let IDTechservices be your trusted partner in advancing non-destructive evaluation efficiency.

Calibration blocks

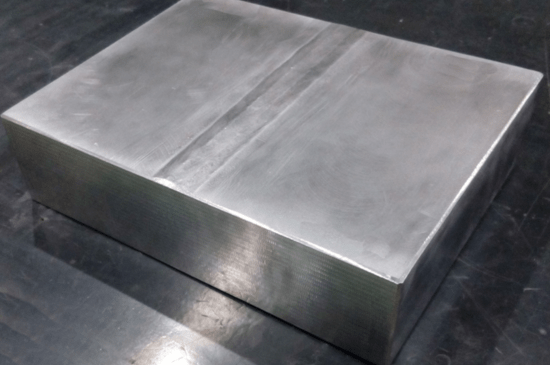

Explore Precision Calibration Blocks at IDTechservices: Setting Standards in NDE Equipment Calibration

Discover our comprehensive range of standard Ultrasonic Testing (UT), Eddy Current, Liquid Penetrant (LP), Radiographic Testing (RT), and Visual Testing (VT) blocks, meticulously crafted to meet both on-site and laboratory inspection requirements. At IDTechservices, we specialize in manufacturing individual or sets of calibration blocks, ensuring precision and adherence to international standards.

Key Features:

Individual or sets of ultrasonic, eddy current, LP, RT, and VT calibration blocks tailored to diverse inspection needs.

All regular calibration blocks manufactured to international standards, guaranteeing reliability and accuracy.

Our expertise extends to crafting custom-designed specialist pieces, manufactured with tolerances as fine as +/- 0.1mm.

From design and NDE to mechanical inspection, 3D CAD modeling, electrical discharge machining (EDM), specialist welding, cladding overlay, machining, bending/rolling, material supply, metallurgy, coatings, paints, to heat treatment – we cover it all.

PDI Reference Blocks:

Elevate your inspection equipment calibration with our PDI reference blocks. These blocks are designed for advanced calibration before performance demonstrations and pipe weld inspections in the power generation industry. Benefit from our in-depth knowledge of non-destructive evaluation (NDE) and performance demonstration, providing unique insights into the requirements of these specialized reference blocks.

Custom Reference Blocks:

IDTechservices brings extensive experience to the table, manufacturing custom blocks that precisely meet your requirements. Our capabilities span NDE, Mechanical Inspection, CAD design, Specialist Welding, Cladding Overlay, Machining, Bending/Rolling, and Heat Treatment.

Reflecting Excellence – We Manufacture the Following Reflector Types:

- Slots

- Notches

- Side Drilled Holes

- Flat Bottom Holes

Request a Quotation:

For a personalized quotation, please provide specifications, detailed drawings, code requirements, and material type/grade. At IDTechservices, we are committed to delivering calibration blocks that set the standard in precision and reliability.

Explore the possibilities with IDTechservices – Your Trusted Partner in NDE Equipment Calibration.

Corrosion and fatigue blocks

Enhance NDT Proficiency with Realistic Industrial Failures in Corrosion, Fatigue, and Erosion Simulation Blocks by IDTechservices

Welcome to IDTechservices, where we redefine NDT calibration blocks by incorporating realistic industrial failures in corrosion, fatigue, and erosion simulations. Our commitment is to elevate your expertise through hands-on training with mock-ups that authentically replicate the challenges of real-world industrial scenarios.

Addressing Persistent Challenges: In the realm of pre and in-service inspection, managing corrosion and erosion remains a persistent challenge. To empower professionals in overcoming these obstacles, we offer NDT calibration blocks that go beyond theoretical knowledge. Our blocks simulate realistic industrial failures, providing a practical learning experience to mitigate risks and reduce the annual costs associated with asset ownership.

Cutting-edge Techniques for Comprehensive Learning: We understand the significance of staying at the forefront of industry advancements. Therefore, our simulation blocks encompass cutting-edge techniques such as Corrosion Under Insulation (CUI) and UT Corrosion Mapping. This ensures that your team gains not only theoretical knowledge but also hands-on skills to effectively address the complexities of corrosion, fatigue, crevice, pitting, and erosion.

Invaluable Insights through Practical Simulations: Our calibration blocks feature typical flaws encountered in industrial settings, including erosion, fatigue, corrosion, crevice, and pitting. This hands-on approach allows professionals to gain invaluable insights and practical experience, enhancing their ability to detect and manage these flaws in real-world scenarios.

Why Choose IDTechservices:

Our NDT calibration blocks simulate realistic industrial failures for an authentic learning experience.

Incorporating advanced methods like Corrosion Under Insulation (CUI) and UT Corrosion Mapping.

Our offerings are customized to meet your specific training and development needs.

With a track record of excellence, we are committed to advancing proficiency in NDT through realistic simulations.

Empower Your Team – Request a Consultation:

Ready to elevate your team’s NDT proficiency? Request a consultation with IDTechservices today. Our realistic industrial failure simulations contribute to the continuous development of your team’s capabilities in corrosion, fatigue, and erosion management.

Choose IDTechservices – Your Trusted Partner in Advancing NDT Expertise through Realistic Industrial Failures Simulation Blocks.

HTHA and HIC block

Unique Expertise in Hydrogen Attack Simulation for Petrochemical Industry NDT Blocks by IDTechservices

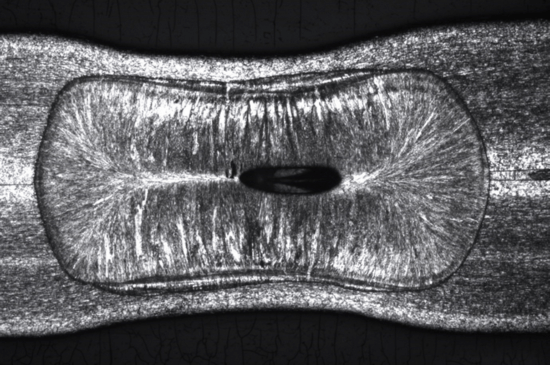

At IDTechservices, we lead the way in creating NDT calibration blocks that meticulously simulate the complex failure mechanisms of Hydrogen Attack in steels and metallic alloys, with a specialized focus on High-Temperature Hydrogen Attack (HTHA) for the petrochemical industry and Hydrogen-Induced Cracking (HIC). Our bespoke blocks are invaluable tools for evaluating defects at their germinal stage, allowing for the prediction of in-service conditions with precision.

HTHA and HIC Simulation: A Specialized Expertise: Our commitment to excellence is evident in our ability to simulate the unique challenges posed by Hydrogen Attack, particularly in the demanding environment of the petrochemical industry. We specialize in creating NDT blocks that accurately mirror the early stages of Hydrogen Attack, providing a crucial advantage in defect evaluation and predicting potential in-service conditions.

Optimizing NDT Techniques for Precise Defect Detection: IDTechservices is at the forefront of defining the correct NDT techniques tailored for the intricate defects induced by Hydrogen Attack. Our blocks enable inspection professionals to hone their skills in using advanced inspection methods, ensuring accurate detection and evaluation of defects. This proficiency is a cornerstone in modifying Risk-Based Inspection (RBI) programs within a plant or refinery, contributing to enhanced safety and reliability.

Micro Crack Generation Expertise: One of our distinguishing features lies in our capability to create blocks with micro-cracks ranging from 10 microns to 500 microns, generated by pure hydrogen environment. This showcases our deep understanding of the nuanced effects of Hydrogen Attack. Our team of experienced engineers, including PhDs specialized in Hydrogen Attack studies, ensures that our NDT blocks provide a comprehensive representation of the challenges faced in real-world scenarios.

Beyond Petrochemical Applications: Defining the Future of Hydrogen Technology: While our NDT blocks find vital applications in the petrochemical industry, the knowledge gained from our studies extends far beyond. It contributes to the definition of materials for hydrogen generation, hydrogen storage, and the development of new car hydrogen engines, positioning IDTechservices as a key player in advancing hydrogen technology.

Why Choose IDTechservices:

Our expertise is dedicated to simulating Hydrogen Attack, with a specific emphasis on HTHA and HIC.

Our NDT blocks allow for the evaluation of defects at the germinal stage, providing predictive insights for in-service conditions.

Our HTHA blocks help to define the correct NDT techniques, enabling professionals to detect and assess defects with precision.

Our unique capability to create blocks with micro-cracks ranging from 10 microns to 500 microns sets us apart in the industry.

Beyond petrochemical applications, our studies contribute to shaping the future of hydrogen technology.

Elevate Your NDT Capabilities with IDTechservices:

Ready to enhance your understanding of Hydrogen Attack? Partner with IDTechservices for cutting-edge NDT blocks and expertise that extend beyond industry boundaries.

Choose IDTechservices – Your Trusted Partner in Advancing Hydrogen Attack Simulation and NDT Innovation.

Training and examination kits and specimens

Enhance Learning with IDTechservices Training and Examination Kits

At IDTechservices, we prioritize knowledge transfer through our comprehensive Training and Examination Kits, designed to elevate the understanding of flaw detection, interpretation, and basic sizing. Whether you are an educational institution, training center, or industry professional, our kits provide a hands-on approach to learning and practical training.

1. Educational Kits:

Our Educational Kits serve as dynamic tools for learning the principles of flaw detection. These kits include a set of miniature welds and macro sections, meticulously crafted to demonstrate flaw detection principles. Each kit is available in three different materials: carbon steel, stainless steel, and aluminum. Custom materials can be accommodated upon request. Housed in durable polypropylene boxes, these kits come with comprehensive support documentation.

Features:

- Miniature Welds and Macro Sections

- Demonstrate Flaw Detection Principles

- Available in Carbon Steel, Stainless Steel, Aluminum

- Comprehensive Support Documentation

2. Standard Flawed Specimens:

Our Standard Flawed Specimens offer practical training in flaw detection, sizing, and interpretation. These small, lightweight specimens are convenient to handle, each containing one or two flaws, with a minimum of 18 flaws per set. Designed for introductory training, each set is presented in a robust polypropylene carry case with high-density foam inserts, ensuring optimal protection for the specimens.

Features:

- Small, Lightweight, and Convenient

- One or Two Flaws per Specimen

- Minimum of 18 Flaws per Set

- Polypropylene Carry Case with High-Density Foam Inserts

- Ideal for Introductory Training

Customization and Beyond: At IDTechservices, we understand the importance of tailored solutions. If you have specific material preferences or customization requirements, our team is ready to assist. We aim to provide the flexibility needed to meet the unique demands of your educational or training programs.

Empower Learning with IDTechservices Kits:

Whether you are shaping the next generation of inspectors or honing your skills in flaw detection, IDTechservices Training and Examination Kits are essential tools for a practical and insightful learning experience.

Choose IDTechservices – Your Trusted Partner in Advancing NDT Education and Training.